High Quality OEM/ODM LED Strip Manufacturer

High Quality OEM/ODM LED Strip Manufacturer

January 21, 2026 37

In pixel LED strips (also known as SPI or addressable LED strips), color order is a technical parameter that is often overlooked—but in real engineering projects, it is one of the most common causes of color errors, commissioning delays, and unnecessary rework.

If color order is not correctly understood and configured, even a perfectly wired system can display the wrong colors.

Color order refers to the sequence in which RGB color data is arranged and transmitted inside each LED pixel.

When a controller sends data to a pixel LED strip, it sends color values in a fixed order. If the controller’s color order setting does not match the LED strip’s internal color order, the colors displayed will be incorrect.

Example:

The controller outputs Red

The LED strip displays Green or Blue

In most cases, this does not indicate a defective product—it means the color order is mismatched.

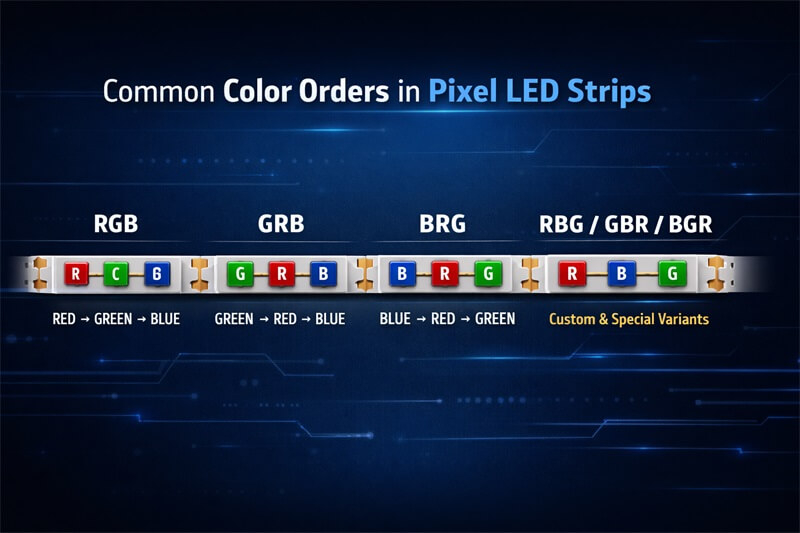

In engineering projects, the most commonly encountered color orders include:

RGB – Red → Green → Blue

GRB – Green → Red → Blue (very common)

BRG – Blue → Red → Green

RBG / GBR / BGR – Used by certain chips or custom designs

WS2812B / WS2813: Usually GRB

WS2811: Commonly RGB or GRB (must be confirmed per batch)

⚠️ Never assume color order based on experience alone. Different chip suppliers and custom configurations may use different sequences.

Incorrect color order can cause several practical problems in projects:

Red appears green

White light looks tinted

Overall lighting effect is inaccurate

Engineers may repeatedly adjust software settings, replace controllers, or suspect wiring issues—wasting valuable time on site.

End users often assume the LED strip is unstable or defective, even though the issue is purely a configuration mismatch.

Professional practice usually follows these steps:

A properly designed engineering-grade pixel LED strip will clearly state the color order in its specifications.

Ensure the controller or software is set to the same color order as the LED strip.

Test Red, Green, Blue, and White individually. This is the fastest and most reliable verification method on site.

In architectural and landscape lighting projects, pixel LED strips are often installed in hundreds or even thousands of meters.

If color order is wrong:

Small projects require reprogramming

Large projects may require complete system reconfiguration

In serious cases, this can lead to:

Delayed handover

Increased labor costs

Client dissatisfaction

That is why color order is not a minor detail—it is an engineering parameter.

Many color order issues arise because:

Specifications are unclear

Different batches use different configurations

No technical support is provided during commissioning

Professional manufacturers design pixel LED strips with:

Consistent color order definitions

Clear documentation

Stable compatibility with mainstream controllers

At ZBL Lighting, pixel LED strips are developed with real project requirements in mind:

Clearly defined and consistent color orders

Full technical documentation for engineering use

Compatibility with common SPI and DMX control systems

Custom color order options for special projects

Our focus is not only on visual effects, but on predictable, reliable performance in real installations.

Color order determines whether a pixel LED strip displays colors correctly.

For every engineering project:

Confirm the color order before installation

Match controller settings precisely

Verify with on-site color testing

This simple step can prevent most color-related issues in pixel LED strip projects.

If you are working on a pixel LED or architectural lighting project and need technical clarification or product support, further discussion is always welcome.

Need professional help? Contact our team for expert support and personalized solutions. We’re here to assist you. Contact Us