High Quality OEM/ODM LED Strip Manufacturer

High Quality OEM/ODM LED Strip Manufacturer

November 26, 2022 1355

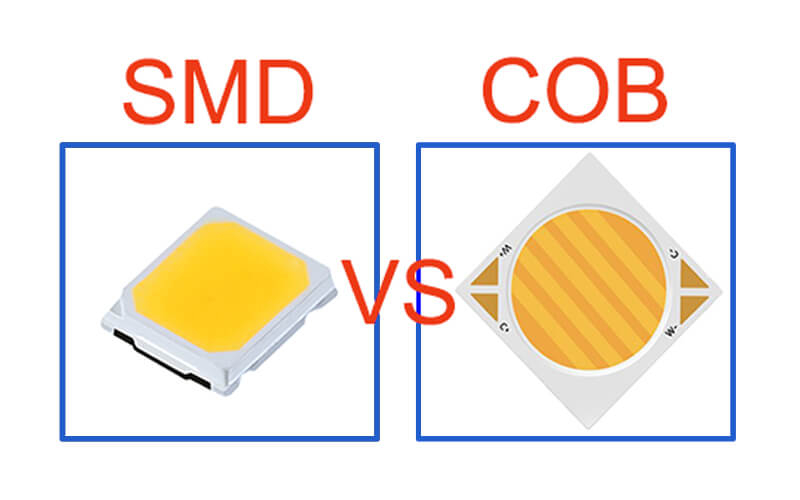

The COB (Chip-on-Board) and SMD (Surface-Mount Device) packaging processes have different characteristics and advantages in LED lighting. Here are the main differences between them:

High Integration: COB packaging integrates multiple LED chips directly onto a single substrate, creating a compact light source. This enhances the uniformity and reduces glare and shadows.

High Brightness and CRI: COB luminaires typically offer higher brightness and Color Rendering Index (CRI), meaning they can provide lighting that is closer to natural light.

Heat Management: COB LED strips usually require more complex heat management systems because multiple LED chips densely integrated together generate relatively more heat. Effective heat dissipation designs are needed to keep the temperature within safe levels.

High Customization: COB LED strips can be highly customized to meet various lighting needs, such as different color temperatures, power levels, and luminous flux.

Larger Size: COB packaging is typically larger than SMD packaging, which means they may be less versatile in certain applications.

Small and Lightweight: SMD LED chips are very small, making SMD LED strips suitable for compact spaces and lightweight applications.

Uniformity: SMD LED strips generally have good light uniformity, though slightly inferior to COB in this aspect.

Versatility: SMD LED strips are suitable for a wide range of applications, from backlighting to indoor and outdoor lighting, as they come in various sizes, colors, and power options.

Simple Heat Management: Due to the smaller size of SMD LED chips, they typically generate less heat, making heat management relatively simple.

Low Power Consumption: SMD LED strips are usually more energy-efficient than COB LED strips, making them suitable for long-term use.

In summary, COB and SMD packaging processes each have their own advantages in LED lighting. The choice between them depends on specific application requirements. COB is suitable for scenarios that require high brightness, high CRI, and uniform lighting, while SMD is versatile and ideal for applications that demand compact size, lightweight, and multi-purpose use. When selecting an LED lighting solution, it's essential to make a wise choice based on the project's requirements and budget.

ZBL Lighting is a professional LED strip manufacturer with a wealth of experience, specializing in COB LED Strip, SMD LED Strip, side LED Strip, high-temperature resistance, ultra-long lifespans, anti-attenuation, high brightness, and mixed-color lighting. Our main product offerings include SMD strips, COB strips, RGB strips, neon tubes, and pixel lights, and we also offer customizable solutions to meet your specific needs. If you have any lighting requirements, please don't hesitate to get in touch with ZBL Lighting.

Need professional help? Contact our team for expert support and personalized solutions. We’re here to assist you. Contact Us