High Quality OEM/ODM LED Strip Manufacturer

High Quality OEM/ODM LED Strip Manufacturer

December 30, 2019 686

Introduction: LED strip lights have become increasingly popular for their versatility and energy efficiency. However, with numerous options available in the market, it's important to consider various factors before making a purchase. In this comprehensive guide, we will explore 12 key factors to help you make an informed decision. We will provide a detailed analysis of each factor, supported by data in the accompanying table.

The lumen (lumens) of LED strip light is the unit used to measure the brightness of its light output, which has an important role in LED lighting. Lumen is used to represent the total amount of visible light produced by an LED strip. Therefore, the lumen value visually tells you how bright the LED strip is. Higher lumen values indicate higher brightness, while lower lumen values indicate lower brightness.

Here is the comparison of the impact of different lumen values on LED light strips in table form:

| Lumen (lm) | Comparison |

|---|---|

| 500 lm | Suitable for general indoor lighting, such as living rooms or bedrooms. Provides enough brightness for daily activities but not ideal for tasks requiring higher brightness. |

| 1000 lm | Suitable for areas like offices, kitchens, or bathrooms where more brightness is needed. It offers good illumination for work, cooking, or reading. |

| 2000 lm | Ideal for commercial spaces that require bright lighting, such as retail stores or restaurants. Also suitable for task lighting in areas like workbenches or study zones. |

| 5000 lm | Typically used in large commercial or industrial spaces, such as warehouses or manufacturing plants. It provides intense illumination for safety and operational needs. |

| 10000 lm | Commonly used for outdoor lighting, such as streetlights or billboard illumination. It can illuminate large areas. |

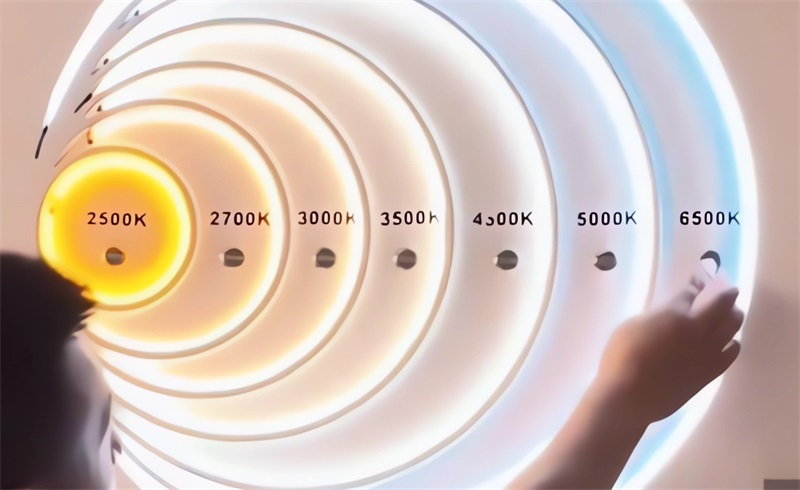

LED light strip color temperature refers to the characteristic color of the light emitted by the LED strip, typically measured in Kelvin (K). Different color temperature values have varying impacts on lighting and ambiance. Here's a brief comparison of different color temperature values, their colors, and common usage scenarios:

| Color Temperature (K) | Color | Common Usage Scenarios |

|---|---|---|

| Below 2700K | Ultra Warm White | Cozy home lighting, bedrooms, dining rooms, creating a warm and inviting atmosphere. |

| 2700K - 3000K | Warm White | Indoor lighting, living rooms, dining rooms, creating a comfortable and welcoming environment. |

| 3500K - 4000K | Natural White | Offices, commercial spaces, providing clear lighting to enhance alertness. |

| 5000K - 6000K | Cool White | Garages, hospitals, task lighting, areas requiring high contrast and accurate color. |

| Above 6500K | Daylight or Daylight White | Supermarkets, workshops, industrial environments requiring intense illumination. |

This table provides a brief overview of different color temperature values, the associated colors, and where they are commonly used. Lower color temperature values tend to emit warm yellowish light, suitable for creating a cozy atmosphere, while higher color temperature values emit cooler bluish-white light, ideal for enhancing alertness and color rendering. Choosing the right color temperature helps meet various lighting needs and emotional effects.

Cutting the length of an LED strip may affect electrical characteristics, brightness, thermal management, control and maintenance, so these factors need to be carefully considered when making cuts to ensure that the new length is adapted to meet lighting needs.

Electrical Characteristics: Trimming an LED light strip may alter its electrical properties. Shortening the strip could affect current and voltage distribution, necessitating a reevaluation of the power driver and wiring design to accommodate the new length.

Brightness: LED light strips typically have current-regulating circuits between each segment to maintain uniform brightness. When you trim the strip, the new segments may have slightly different brightness levels, requiring adjustments to match the surrounding areas.

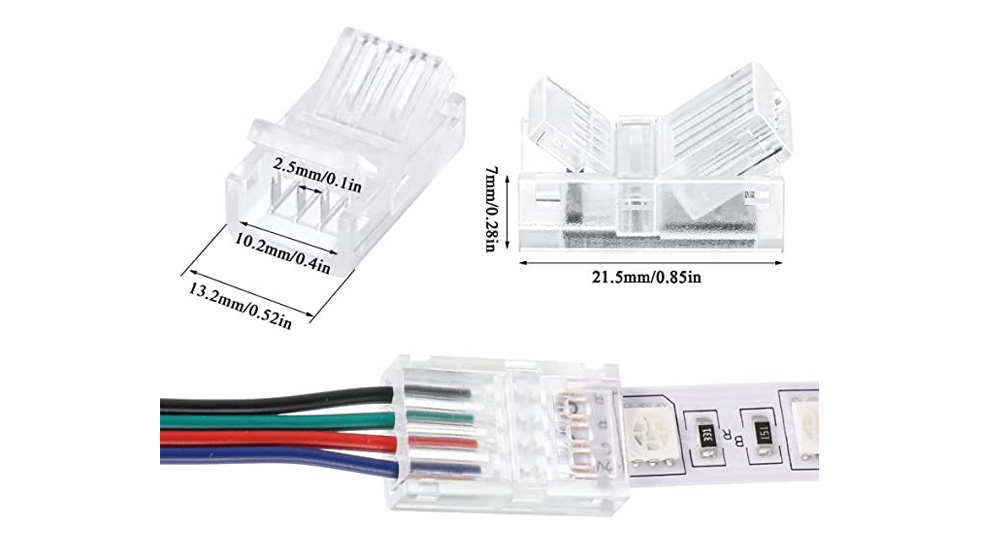

Connections and Wiring: Cutting an LED light strip may require reconnecting wires, adding extra cables and connectors, potentially increasing the complexity of the cabling.

Heat Management: Longer LED light strips usually have better heat dissipation due to a larger surface area. Trimming the strip may concentrate heat on smaller segments, potentially requiring additional heat management measures.

Control and Dimming: If you use dimming or color control features, trimming the LED light strip necessitates ensuring that the control system can still manage the new length. Some control systems may require reprogramming or reconfiguration.

Maintenance and Replacement: After trimming an LED light strip, future maintenance and replacement might become more complex as you'll have more connections and segments to deal with, requiring additional work for upkeep and repairs.

Brightness Distribution: Trimming an LED light strip can lead to uneven brightness distribution. This might require additional optical design to achieve the desired lighting effect.

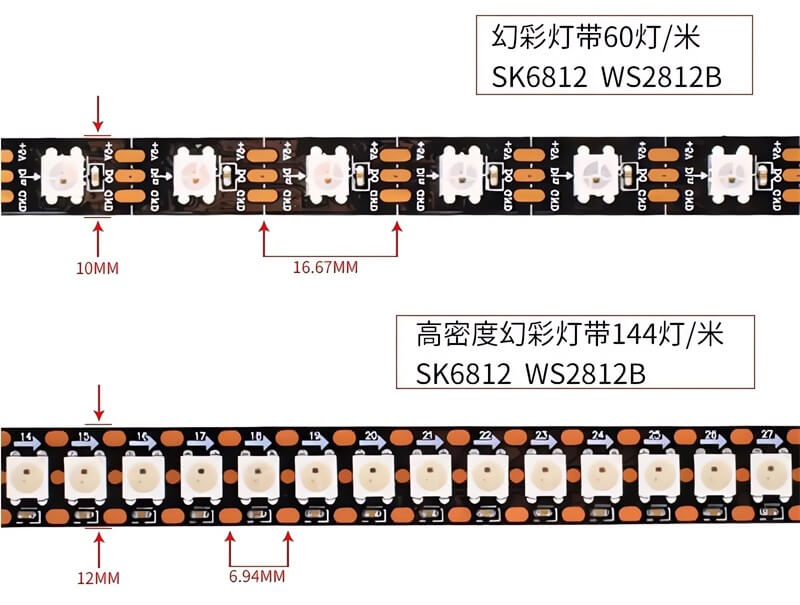

Every 3 LEDs or Every 5 cm: This is one of the most common cutting distances, especially for standard 12V and 24V LED light strips. You can trim the strip every 3 LEDs or every 5 centimeters as needed.

Every 6 LEDs or Every 10 cm: For some brighter or denser LED light strips, larger cutting units may be required. Hence, cutting every 6 LEDs or every 10 centimeters is common.

Every 2 LEDs or Every 3.33 cm: Certain LED light strips offer higher resolution and cutting flexibility, allowing trimming every 2 LEDs or every 3.33 centimeters. This can be useful for specific applications.

Custom Lengths: Some LED light strips allow users to customize the cutting length to meet specific project requirements, often by marking specific cutting lines. This enables the creation of lighting effects with exact lengths.

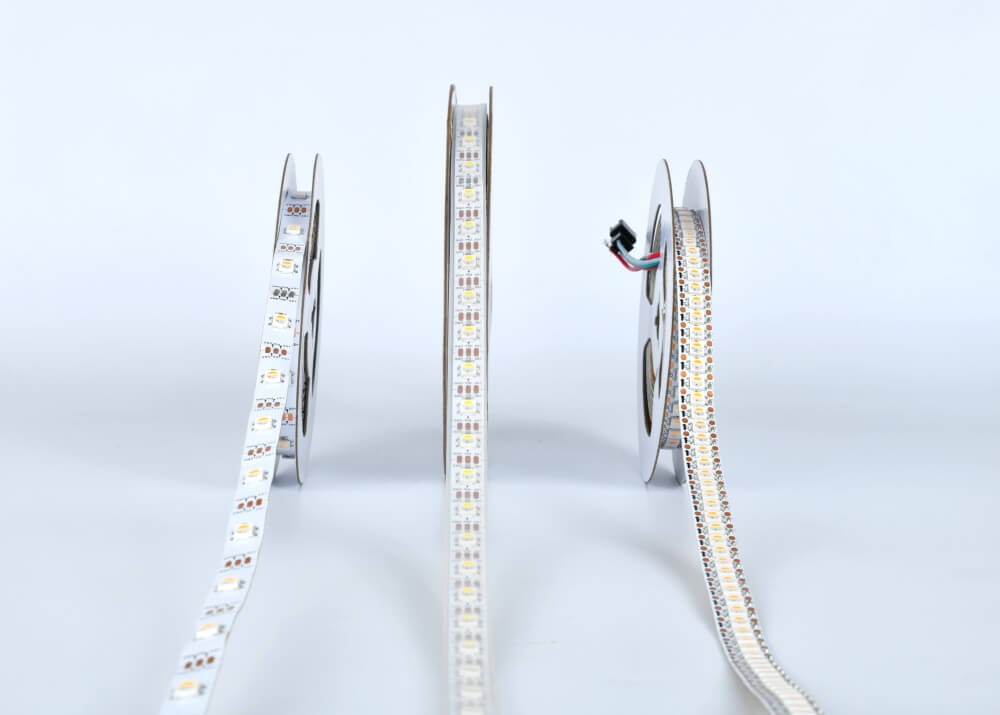

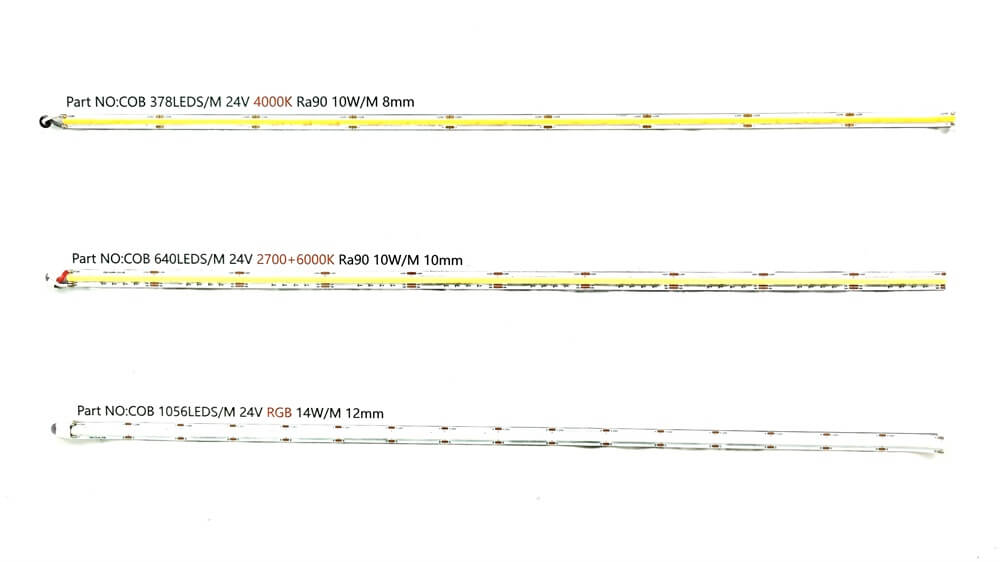

The width of an LED light strip refers to the cross-sectional dimension of the strip and is typically measured in millimeters (mm). Different widths of LED light strips can have various effects and impacts on their performance and suitability for different applications. Here are the potential effects and influences of different LED light strip widths:

Brightness and Uniformity: Wider LED light strips can typically accommodate more LED chips, which may result in higher brightness for a given length. Additionally, wider strips are often better at providing a uniform light distribution, reducing the likelihood of uneven brightness.

Heat Dissipation: Wider LED light strips usually have a larger surface area, which aids in heat dissipation. This can help lower the operating temperature of the LEDs, extending their lifespan. This is particularly important for applications that require continuous operation and long-lasting LED strips.

Decorative Effects: The broader width of an LED light strip allows for a wider light projection, making it suitable for creating more extensive decorative effects, such as illuminating larger wall surfaces, ceilings, or floors.

Installation Complexity: Wider LED light strips may require more installation space, which could be a challenge in tight spaces or when concealment is necessary. Additionally, broader strips might need more substantial support structures to ensure secure installation.

Power Consumption: Wider LED light strips typically require more power to supply the additional LED chips, potentially leading to increased energy consumption. This should be considered in terms of budget and energy efficiency.

Aesthetics and Design: The width of an LED light strip can significantly impact the overall aesthetics and design of a space. Wider strips may be more prominent and become a part of the decor, whereas narrower strips are easier to conceal.

Here is a brief comparison table of common LED light strip widths:

| Width (mm) | Key Features | Typical Applications |

|---|---|---|

| 3mm | Very narrow, suitable for detailed decoration. | Outline lighting, decorative strips, Automotive, Seam small spaces. |

| 5mm | Relatively narrow, versatile. | General indoor lighting, decoration, task lighting. |

| 8mm | Common width, balances brightness and uniformity. | Indoor lighting, outline lighting, decoration, task lighting. |

| 10mm | Common width, versatile. | General indoor lighting, decoration, task lighting. |

| 12mm | Common width, provides good brightness. | Indoor lighting, commercial lighting, decoration. |

| 15mm | Relatively wide, suitable for applications requiring higher brightness. | Commercial lighting, large area illumination. |

| 20mm and wider | Very wide, suitable for large lighting projects. | Outdoor lighting, billboard lighting, display shelf lighting. |

This table provides a comparison of various LED light strip widths, their key characteristics, and typical applications. The choice of width depends on factors such as brightness requirements, desired lighting effects, and installation needs.

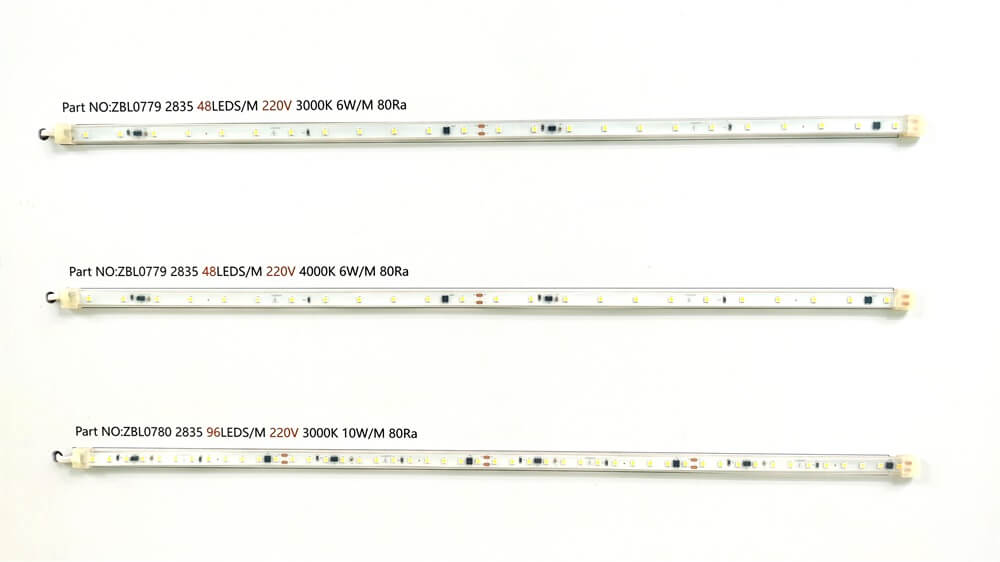

LED strips with different voltages can have different impacts in terms of brightness, power consumption, current, voltage drop, safety and installation. Below is a comparative table of common LED strip voltage levels:

| Characteristics | 5V LED Strip | 12V LED Strip | 24V LED Strip | 110V LED Strip | 220V LED Strip |

|---|---|---|---|---|---|

| Brightness | Generally lower | Moderate | Generally higher | High | High |

| Power Consumption | Higher | Moderate | Lower | High | High |

| Current | Higher | Moderate | Lower | High | High |

| Voltage Drop | Noticeable | Moderate | Smaller | Not applicable | Not applicable |

| Safety | Very safe | Relatively higher | Higher but needs caution | High, typically requires professional installation | High, typically requires professional installation |

| Heat Dissipation | Low voltage usually generates less heat | Moderate | Requires good heat dissipation | Typically requires good heat dissipation | Typically requires good heat dissipation |

| Installation Complexity | Relatively easy installation | Typically easy installation | Typically easy installation | Requires professional installation | Requires professional installation |

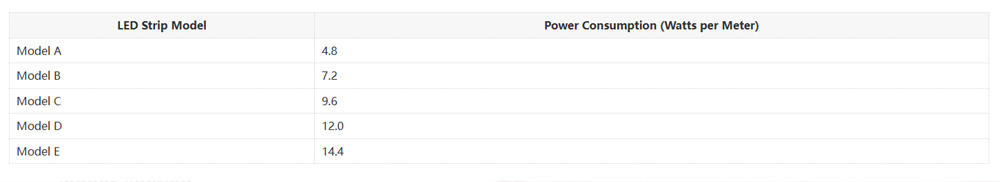

2021: New ErP and Energy Label Directives for LED Lighting Unveiled, measured in watts per meter (W/m), determines the energy efficiency of the LED strip.

While LED light strips are already highly energy-efficient, in the current era of energy scarcity, their power consumption is undeniably a crucial factor to consider in every lighting project. The most straightforward representation of LED light strip power consumption is the power per meter.

By comparing the power per meter, we can swiftly discern the disparities between different LED light strips. For instance, an A-grade energy-efficient LED light strip may consume only half the power of a C-grade LED light strip. This metric provides a quick and telling insight into their efficiency and impact on energy conservation.

The protection rating of LED strip light refers to its waterproof and dustproof performance, which is usually expressed by IP (Ingress Protection) rating. The importance of the Ingress Protection rating is that it determines what kind of environment and use the LED strip light is suitable for.

The IP rating, which stands for Ingress Protection, comprises two parts: the "I" rating and the "P" rating.

I Rating (Ingress Protection): The "I" rating represents the product's dust protection level and is indicated by a numerical value from 0 to 6. This number signifies the product's ability to resist the ingress of dust, with 0 indicating no dust protection and 6 indicating complete dust protection. A higher number indicates stronger dust protection.

P Rating (Protection against water): The "P" rating signifies the product's water protection level and is represented by a numerical value from 0 to 9K. This number reflects the product's ability to resist the ingress of water, with 0 indicating no water protection and 9K indicating robust protection against high-pressure water jets. A higher number indicates stronger water protection.

Here are some common IP (Ingress Protection) ratings from IP20 to IP68, along with their meanings and protective functions:

| IP Rating | Meaning | Protective Function |

|---|---|---|

| IP20 | Dust-proof, no water resistance | Suitable for indoor use, providing basic dust protection. |

| IP44 | Dust-proof, splash-resistant | Suitable for indoor and outdoor use in damp conditions, protecting against small splashes. |

| IP65 | Dust-proof, jet-proof | Suitable for outdoor and wet environments, guarding against larger splashes and water jets. |

| IP67 | Dust-proof, immersion-proof | Suitable for outdoor use, capable of short-term immersion without damage. |

| IP68 | Dust-proof, continuous immersion-proof | Suitable for underwater applications, capable of prolonged submersion without damage. |

Here are some common dimming methods for LED light strips along with their key characteristics:

| Dimming Method | Characteristics |

|---|---|

| PWM Dimming (Pulse Width Modulation) | - Adjusts brightness by controlling the width of current pulses. - Provides a wide dimming range and smooth dimming effects. - Typically requires a dedicated PWM controller. |

| Resistor-based Dimming | - Modifies brightness by changing the resistance to control current. - Simple but may have a limited dimming range. |

| 0-10V Dimming | - Uses a 0-10V voltage signal to control brightness. - Suitable for commercial lighting and building automation systems. |

| DALI Dimming (Digital Addressable Lighting Interface) | - Uses digital signaling, supporting multiple devices and scenes. - Suitable for large commercial and building projects. |

| Wireless Dimming | - Employs radio frequency or Wi-Fi signals for remote wireless control. - Offers convenient dimming options, suitable for smart homes. |

| Smart Dimming | - Integrates with smart lighting systems, allowing automatic dimming based on time, brightness, and scenes. - Provides highly personalized and energy-efficient lighting control. |

These are some common dimming methods for LED light strips, each with its unique characteristics. The choice of dimming method depends on specific project requirements and design considerations.

Connectivity options determine the method of connecting and installing the LED strip. Option A offers plug-and-play connectors, Option B provides connectors for customization, and Option C requires soldering for installation. Consider your technical expertise and the desired level of customization when evaluating connectivity options.

LED light strip is usually labeled service life, half of the common 20,000 hours -50,000 hours, there are some high-quality LED light strip manufacturers can be used, 50,000-100,000 hours, the longer the life of the LED light strip, which also represents the difference in quality, but at the same time there will be some differences in price.

Energy consumption, measured in watts (W), determines the overall power usage of the LED strip. Option A consumes 120W, Option B consumes 200W, and Option C consumes 320W. Consider the energy efficiency and operational costs associated with different energy consumption levels.

The Color Rendering Index (CRI) holds significant importance in lighting projects as it directly influences lighting effectiveness, color rendition, and visual comfort. Here's why CRI is essential in lighting:

Color Rendition: CRI measures a light source's ability to accurately reproduce the colors of objects. A higher CRI indicates that the light source can faithfully render object colors, making them appear more natural. This is crucial in fields like art, design, commercial displays, and medical applications where accurate color reproduction is vital for visual perception.

Visual Comfort: Light sources with a high CRI typically provide a more natural and soft lighting effect, reducing glare and visual fatigue. This is essential for long-duration use, office lighting, and creating comfortable living spaces.

Safety: In certain areas such as medical operating rooms and laboratories, accurate color recognition is crucial for safety. High-CRI lighting helps prevent misjudgments and errors.

Product Display: In commercial lighting, CRI is critical for enhancing the attractiveness and authenticity of displayed products. High-CRI lighting can improve the appearance of goods, attracting more consumers.

Lighting Design: Lighting designers often choose the appropriate CRI based on project requirements to ensure the desired lighting effect. Different scenarios may require different CRI lighting solutions.

CRI is a key metric for assessing lighting quality, affecting lighting performance, visual perception, and safety. When selecting the right lighting solution, CRI should be considered to meet specific project needs.

Here's a comparison of common CRI (Color Rendering Index) levels:

| CRI Level | Color Rendering | Key Features |

|---|---|---|

| < 80 | Poor color rendering | Colors may appear inaccurate and distorted. Suitable for low-demand lighting scenarios. |

| 80 | Moderate color rendering | Provides moderate color accuracy, suitable for general lighting needs such as typical home lighting. |

| 90 | Good color rendering | Capable of accurately rendering colors and suitable for applications with higher color accuracy requirements, like commercial displays and medical use. |

| 95 | Very good color rendering | Offers very accurate color rendition, suitable for high-demand applications such as art, design, and color-sensitive tasks. |

| 97 | Near-perfect color rendering | Provides extremely high color accuracy and is suitable for extremely demanding applications such as museums and professional lighting design. |

These CRI levels indicate a light source's color rendering ability, with higher CRI typically indicating more accurate color rendering. The choice of CRI level depends on specific application requirements, with higher CRI levels generally used in scenarios demanding high color accuracy, and lower CRI levels suitable for less stringent lighting needs.

Conclusion: By carefully considering these 12 factors, you can confidently select the LED strip lights that best suit your needs. Whether it's for ambient lighting, task lighting, or decorative purposes, an informed decision will ensure optimal performance and satisfaction. Remember to assess each factor based on your specific requirements and preferences. With the right LED strip lights, you can transform any space with beautiful and energy-efficient lighting.

Need professional help? Contact our team for expert support and personalized solutions. We’re here to assist you. Contact Us